More About Helicopter Replacement Parts

Table of ContentsHelicopter Replacement Parts Can Be Fun For EveryoneHelicopter Replacement Parts Things To Know Before You Get ThisGetting My Helicopter Replacement Parts To WorkSee This Report on Helicopter Replacement Parts

With this joint, when one blade flaps up, the other flaps down. Flapping is brought on by a sensation referred to as dissymmetry of lift. As the airplane of turning of the rotor blades is tilted as well as the helicopter starts to move on, an advancing blade and a pulling away blade become well established (on two-bladed systems).

This creates greater lift to be developed on the advancing blade, causing it to rise or flap. When blade rotation reaches the point where the blade becomes the pulling back blade, the additional lift is lost as well as the blade flaps downward. [Figure 5] Fully verbalized rotor blade systems supply joints that enable the blades to move fore as well as aft, in addition to up as well as down.

When initially beginning to rotate, the blades delay up until centrifugal force is completely developed. As soon as revolving, a decrease in speed causes the blades to lead the major blades hub until pressures enter equilibrium. Consistent changes in rotor blade rates create the blades to "search." They are complimentary to do so in a completely verbalizing system due to being mounted on the upright drag hinge.

The Definitive Guide for Helicopter Replacement Parts

Toward that end, the usage of elastomeric bearings in main blades systems is raising. These polymer bearings have the ability to flaw and return to their initial shape. Thus, they can take in resonance that would typically be moved by steel bearings. They also do not need normal lubrication, which decreases upkeep.

These are hubs as well as center components that are made out of sophisticated composite products. They are made to take up the forces of blade hunting as well as dissymmetry of lift by bending. Thus, many hinges and bearings can be gotten rid of from the custom major blades system. The result is an easier rotor mast with lower maintenance because of fewer moving parts.

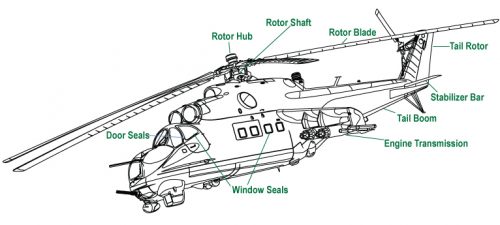

[Number 7] Generally, helicopters have between two and seven this link major rotor blades. These blades are generally constructed from a composite framework. The big rotating mass of the main rotor blades of a helicopter produce torque. This torque increases with engine power and also attempts to spin the fuselage in the contrary instructions.

Regulated with foot pedals, the countertorque of the tail blades should be regulated as engine power degrees are changed. This, in turn, transforms the amount of countertorque, and the airplane can be rotated concerning its upright axis, allowing the discover this pilot to regulate the direction the helicopter is encountering.

9 Simple Techniques For Helicopter Replacement Parts

This reduced stress causes a pressure counter to the torque generated by the main blades. In addition, the remainder of the air from the fan is sent out through the tail boom to a vent on the aft left side of the boom where it is eliminated. This action to the left triggers a contrary response to the right, which is the direction needed to counter the major rotor torque.

It can be relocated any type of instructions to tilt the plane of rotation of the rotor blades. This triggers the helicopter to relocate the direction that the cyclic is moved. As specified, the foot pedals manage the pitch of the tail rotor blades therefore balancing main rotor torque. Figures 11 as well as 12 highlight the controls found in a common helicopter.

Several rotor designs as well as setups have actually been applied over time. Single main rotor helicopters are the most typical sort of helicopter They need an anti-torque gadget (tail rotor or other anti-torque system) to neutralize the twisting energy created by the main blades, which is powered by several engine(s).

Some Of Helicopter Replacement Parts

One of the most typical anti-torque gadget is a tail blades, which is created to compensate the torque produced by the major blades. EC25 single major blades helicopter A tandem rotor helicopter the original source has 2 major rotor systems and no tail blades. Normally the rear blades is installed at a higher placement than the front rotor, and both are created to avoid the blades clashing, must they flex right into the other blades's pathway.

The design of the drive and also control system are much more complicated than the among a single major rotor helicopter (helicopter replacement parts). Ch47 Chinook helicopter with tandem blades Coaxial rotors are 2 primary blades installed on one mast, sharing the very same axis of rotation yet turning in contrary directions, one in addition to the other.

The helicopter will certainly yaw to the left if the clock wise revolving rotor creates more lift, as well as it will yaw to the right if more lift is generated by the counter-clock smart revolving rotor. The drag created by the rotors is rather huge because of the disturbance of airflows, so these helicopters do not usually have a high cruising speed.